How thick can a laser cutter cut wood? As much as laser cutters are versatile tools for woodworking, it comes with some limitations. It has a maximum cut depth, so you have to choose your wood type and cutter properly.

In this post, I will discuss how laser cutters work, their maximum cutting capacity, and tips you can use on your next projects.

What is a laser cutter?

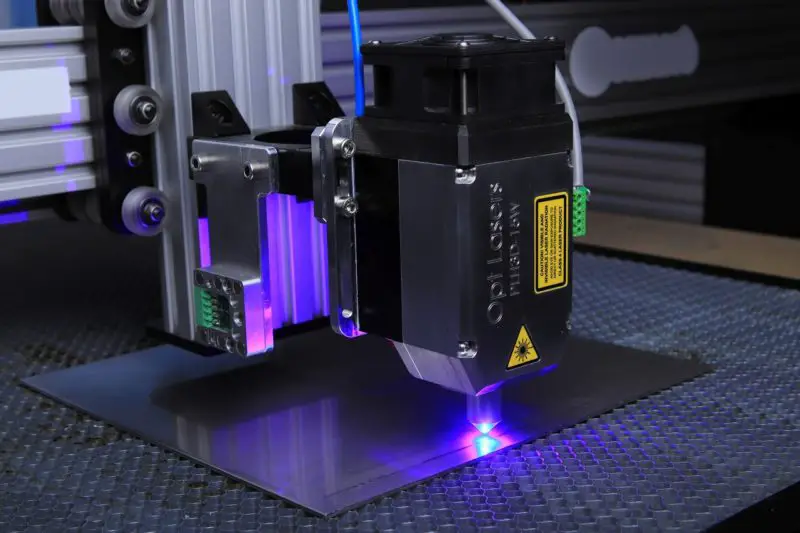

Laser cutters are woodworking tools that use a concentrated laser beam to cut through various materials like wood, plastic, paper, and even glass. It’s often used on wood to create patterns, shapes, lettering, and other designs.

Take note that laser cutters aren’t meant to split wood, especially thick ones. It’s a handy tool if you want to make intricate wooden patterns without using other specialized tools.

Unlike blades, laser cutters provide smoother and seamless results. As a result, it’s now a common replacement on many woodworking tools and even scalpels in the medical world.

In woodworking, laser cutters are used to mark and engrave. It can also cut thin wood pieces, depending on the wattage and cutting depth of the specific model you have.

Like any cutting tool, laser cutters come in different cutting thicknesses and technology. Below, I discuss the most common laser cutter types to see which one suits your project best.

Overall, laser cutters vaporize the materials it gets in contact with. This is how it gets to cut through the wood using its movable head.

Types of laser cutters

When it comes to laser cutters for woodworking, you have two options: a diode or a CO2 technology. Here’s how each one differs:

Diode laser cutters

These laser cutters are available in various colors like blue, red, and green. Compared to the CO2 type, diode laser cutters are weaker, but they can still give a nice cut.

For woodworking, a diode laser cutter is the best bet for marking and etching. You can also use this to cut soft and thin wood materials.

Most of the time, diode laser cutters are reserved for small projects. You may also need to perform multiple passes if you want to cut wood with it.

Overall, most diode laser cutters are available in 1W to 10W options, which works but is not as powerful as CO2 models.

CO2 laser cutters

For more intensive wood cutting needs, a CO2 laser cutter is a good choice. This laser is available in different wattages and sizes, which affects the wood thickness it can cut. But just like diode laser cutters, CO2 lasers can engrave, etch, and mark.

Most CO2 laser cutters are available in 30W to 120W, which is way more powerful than the other type. Nevertheless, both diode and CO2 laser cutters go hand in hand for various woodworking projects.

How thick of wood can a laser cutter cut?

Both diode and CO2 laser cutters have varying cutting tolerance when it comes to wood. It all boils down to their power, which is often measured in watts.

Here’s a quick rundown of the wood cutting capacity of both laser cutter types:

Diode laser cutters

- 1 watt – wood pieces less than 2.5 mm thick and with multiple passes

- 6 watts – wood pieces that are 2 to 3 mm thick in a single pass; multiple passes for thickness up to 5 mm

- 8 watts – single pass on wood pieces not thicker than 5 mm

- 10 watts – single pass on wood not thicker than 5 mm; multiple passes for up to 10 mm thickness

CO2 laser cutters

- 30 watts – wood pieces that are less than ¼ inch thick

- 40/45 watts – wood pieces up to ¼ inch thick

- 60 watts – wood pieces up to ½ inch thick

- 90/100 watts – wood pieces that are ½ inch thick

- 120 watts – wood pieces that are ½ to ¾ inch with multiple passes

Basically, if you need to cut thicker and harder wood, you need to invest in a more powerful laser cutter. Take note that the thickness of the wood is one thing, but the wood type is another story.

For example, a ¼ inch slab of white pine is way faster and easier to cut than a slab of oak with the same thickness. This is why you should always check the wood type you’re working on to get the best results.

Wood types you shouldn’t cut on a laser cutter

Take note that laser cutters use a technology that could react negatively to certain wood materials. Therefore, if you’re new to this tool, you should never cut the following wood types on it:

- Fiberboard. This pressure-treated wood material has glue, which makes it hard to cut through the grain. Also, the laser will burn the glue, which will produce harmful fumes.

- Plywood. Similar to fiberboards, plywood has glue that will inhibit the cutting capacity of the laser cutter.

- Oak and bamboo. These wood types are highly fibrous and would result in uneven depth when cut in a laser cutter. While it won’t hurt to try, cutting oak and bamboo on this tool will yield poor results.

- Oleander. The oleander plant is toxic in all its parts. Laser cutting it would burn portions of the wood, which will unleash toxic fumes. Whether you’re just engraving or marking, you should never use oleander under a laser cutter.

Tips in laser cutting wood

To achieve the best results on your first laser cutting project, you can use the following tips:

- Prepare your materials. The smoke produced during the cutting process can stain the sides of your pattern. To prevent this, you simply have to cover the sides with masking tape. After cutting, just peel the tape off.

- Observe the path distance. When laser cutting wood, the distance between the two cutting paths should be the same as the thickness of the material. If you’re laser-cutting a 3 mm wood piece, the paths’ distance from each other should be 3 mm as well.

- Manage the pulse rate. Laser cutters have an adjustable pulse, which you can utilize to have a smoother finish on the wood. This will also reduce the charred appearance of the edges.

- Pay attention to the wood grain. Before you cut or engrave using a laser cutter, you must check the wood grain position. You’d want to keep the pattern parallel to the grain for the best results.

- Perform test cuts. Before you work on your actual wood piece, it’s best to conduct a test cut. This will let you check the settings of the laser cutter and adjust it accordingly. It will save you from wasting wood.

Is it dangerous to laser cut wood?

Laser cutting should be done with proper caution to prevent burns. You should also keep in mind that not all materials are suitable for laser cutting.

Some types of plastic, wood, and metals will emit toxic fumes if laser-cut. If you got exposed to the harmful gasses, you might get poisoned in a matter of hours.

Aside from that, you should wear protective gear to prevent eyes, throat, and nose irritations. You should also maintain your laser cutter so that it will work efficiently for every project.

Can laser cutters cut your skin?

You have to be careful when using laser cutters as they can burn through the human skin. You can suffer from severe burns and injuries if you accidentally got your hand under the laser. Since accidents can’t be predicted, you should wear protective gloves to prevent injuries.

How much does a laser cutter for wood cost?

Laser cutters for wood vary in price, depending on their wattage and capacity. For high-quality laser cutters, you may have to invest around $4,000. These are the types used on woodworking shops and large projects.

Basically, the higher the wattage is, the more expensive the laser cutter will be. If you’re just starting out, you can find cheaper models that you can use for practice and small projects.

What are the disadvantages of laser cutting?

One of the most common downsides of laser cutting is its limitation in terms of thickness capacity. It’s reserved for thin materials. Also, you can’t use a laser cutter on all materials. Glued, treated, and toxic items will release fumes when placed under the laser cutter.

Conclusion

How thick can a laser cutter cut wood? It can range from 2.5 mm to half an inch. Depending on the specific laser cutter model, you can stretch the thickness to ¾ of an inch with multiple passes.

Aside from the thickness, you should also know what wood material you can’t cut on a laser cutter. This will keep you safe while working on your next project.